NPDI Lead Time Reduction Challenge: Achieving Greater than 50% Reduction in Lead Time for the Customer with TLM

Improving the customer experience is always a top priority at Toyota. We want to put the customer first, and the one way we do that is to continuously shorten and improve the time it takes to deliver the product.. Reducing lead time is one of the main goals of Lean thinking and it is part of Toyota’s Annual Operating Plan. The factory is working on reducing the lead time until the trucks are shipped to the dealerships, so the Toyota Lean Management (TLM) team decided to work with a dealership on their portion of the truck’s lead time.

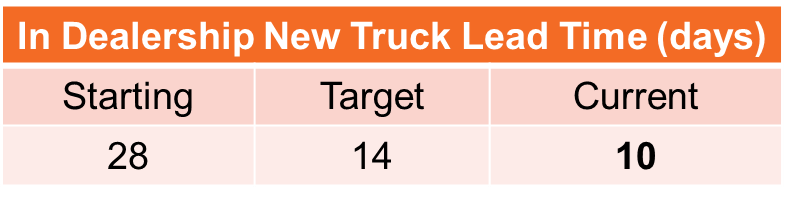

The Indianapolis branch of ProLift accepted the opportunity to work on the challenge to reduce their New truck Pre-Delivery Inspection (NPDI) lead time by 50%, and apply Toyota Lean Management culture and skills to the process. The lead time to be reduced is from when the branch receives the truck from the factory to the time the truck is delivered to the customer. Over a 5-month timeframe, the ProLift Indianapolis team led by Regional Manager, Dave Toneges, and Service Manager, Marcus Whobrey, were able to reduce the Lead time by 65%, from 28 days to 10 days.

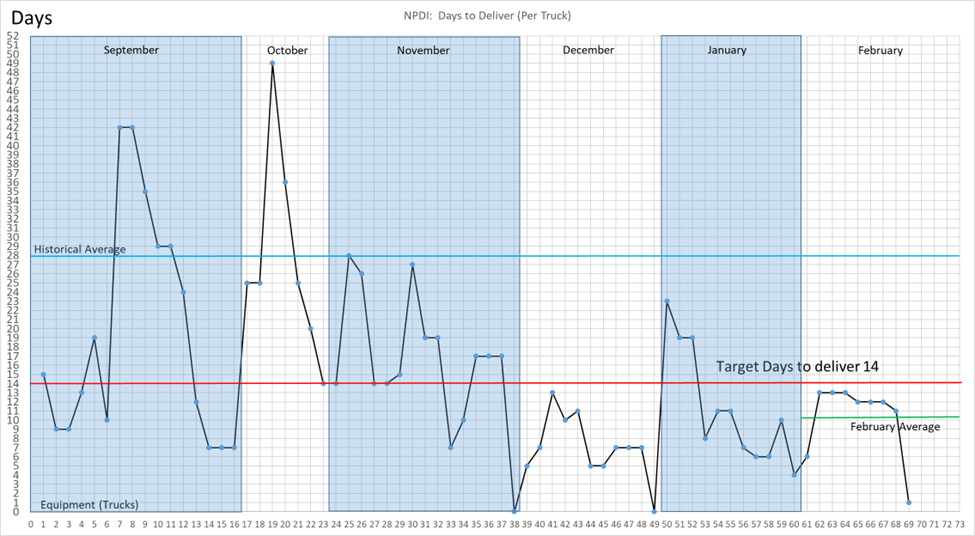

Where do you start when trying to improve? You can’t improve what you don’t measure, so we must begin with measuring the current state. ProLift gathered data and determined the historical average for the last quarter was 28 days.

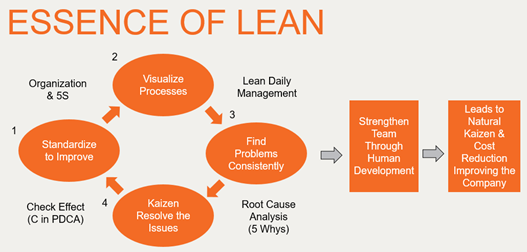

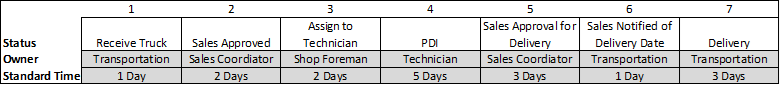

Then, we followed the Essence of the Lean Cycle. We needed to know what the current standard was for the NPDI process. ProLift met as a team with all stakeholders in the process and mapped their current process. Also, they determined the standard times for each part of the process, along with the owner of each step.

The original 7 standard steps to process a New Truck from receipt to Delivery at the beginning of the activity.

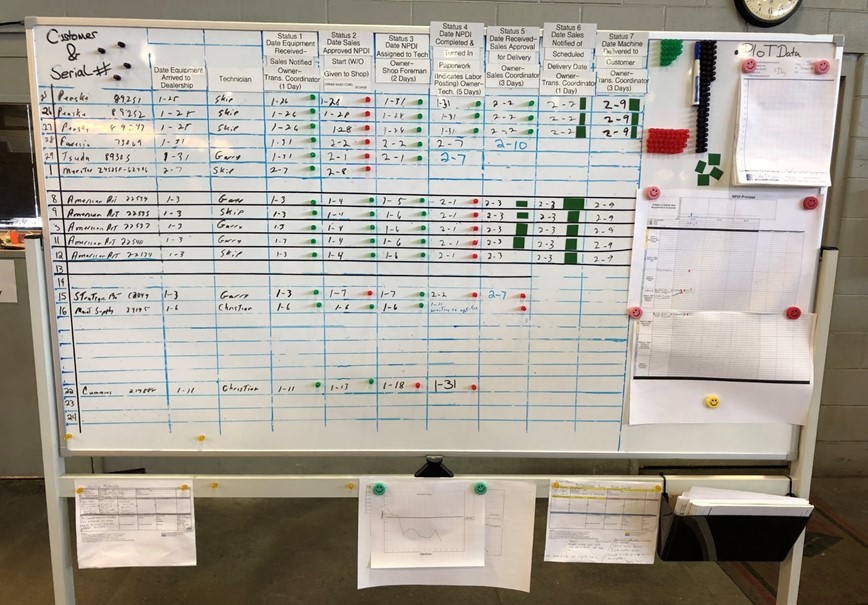

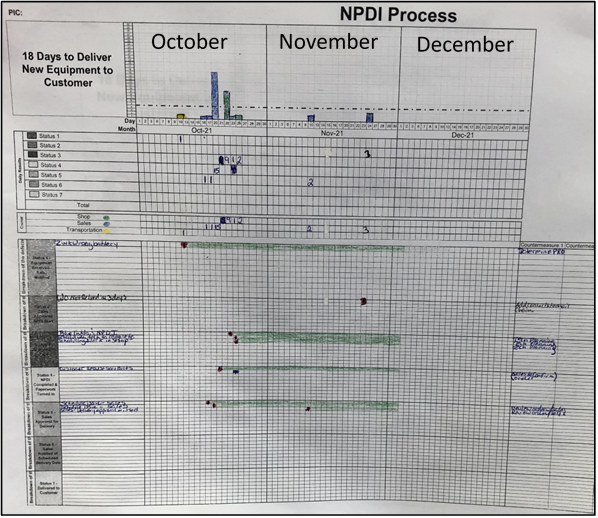

Then, they created a visual board to show the status of each truck in that process. This showed the whole team where the problems were occurring in their process. The goal of visualization is to see problems, so we know what to work on.

The NPDI Status Visualization Board with Weak Point Management and Daily Metrics

ProLift held daily meetings at the board with their team to look at the problems together, make immediate corrections and implement long-term countermeasures. A huge part of Lean culture is not blaming people for problems, so when the ProLift team would see problems in their daily metrics, they did not attack each other. Instead, they focused on how to improve the process.

The NPDI Status Visualization Board with Weak Point Management and Daily Metrics

One of the key methods used to attack the daily problems was Weak Point Management. This is a method that visualizes defects in a process, root cause analysis, what was done to correct the problem, and the effectiveness of the correction. ProLift had determined the amount of time for each of the 7 steps that it took to process a NPDI truck through their shop. When any one of the seven steps went over the standard time, they followed the Weak Point Management process and implemented corrective actions.

ProLift used their daily visualization to identify two problem areas to improve, the PDI work itself done by the technician and the process for approving work orders for the shop. They tackled the time to approve work orders first. The ProLift team worked together to identify their current state, and determine kaizen actions. They decided to make sure work orders were always ready before the truck arrives, reducing the time for status 2 from 2 days to zero days.

The time it took to do a PDI was reduced by 35% through a kaizen event with technicians in the shop. We observed, timed, and optimized the process with the technician’s help.

PDI Process Kaizen Activity Reduced PDI time by 35%. Team (Left to Right): Dave Toneges (Regional Manager), Marcus Whobrey (Service Manager), Tim Brisson (Technician), Andrew Salmon (Shop Foreman), Christian Arbuckle (Technician), and Craig Lyon (TLM Lean Consultant)

Through all of this work in the Toyota Lean Management program, ProLift improved its communication, teamwork, and their ability to see and solve problems resulting in a lead time reduction from 28 days to 10 days. ProLift is looking forward to continuing its Lean journey and reaching a new challenge target of a 5-day average lead time for new trucks by continuing to apply the Lean culture and skills they used in the TLM process.

Reduction of Lead Time from 28 day average to 10 day average (each dot is one truck)