Conger, led by the leadership of Anika Conger Capelle, was a 2021 President’s Award recipient, which is Toyota Material Handling’s highest honor for its Dealers. When a Dealer is performing at a high level, they are achieving success across all facets of their business. This is certainly the case with Conger, and one area that stands out is Conger’s commitment to innovation in their business. Two examples of innovative solutions in their Green Bay, WI branch includes:

- Virtual Service Board

- Tech Bins / Lockers

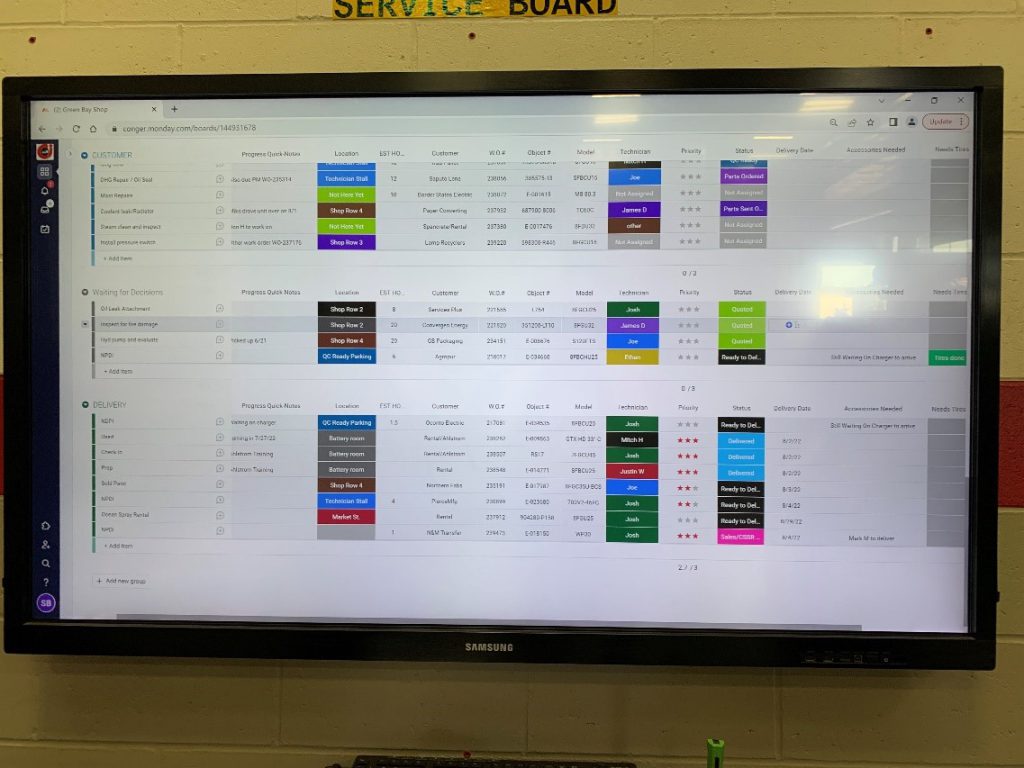

Virtual Service Board

One of the challenges every dealership encounters is determining how to efficiently communicate the status of service work internally as well as to customers. Prior to transitioning to a virtual service board, Conger’s salespeople would routinely call in to check on their customer’s equipment that was being repaired so they could keep them updated on the progress. This involved multiple touch points and considerable time to retrieve and update the information requested by office staff.

The virtual shop board allows Conger to employ visible management and significantly improve communications with the following benefits:

- This is a web-based platform (Monday.com) that allows the sales team or other users to check their repair status remotely without needing to contact the office staff.

- The physical service board is a touchscreen allowing technicians to quickly update a repair status or provide notes regarding the repair.

- The visual awareness created from this service board follows Toyota’s best practices and has improved service management to efficiently prioritize repair jobs.

Tech Bins / Lockers

- The layout for these Tech Bins/lockers was designed to eliminate Muda by reducing the unnecessary time technicians typically spend retrieving customer parts as well as their own paperwork and uniforms.

- The bins allow parts to flow straight through Conger’s parts warehouse to eliminate Muda in the form of movement.

- Parts are received at the loading dock on the opposite side of the parts warehouse, checked in at the shipping counter, and distributed straight to the parts shelves or tech bins/lockers.

- The tech entrance is located straight across from these bins/lockers allowing a minimal number of steps to access them.

- The clear doors allow technicians to quickly recognize if they have parts staged for repairs.

- The bins are designed to hold new uniforms as well as customer paperwork to create a central location for everything the technician needs to be ready to service their customers.