During a recent Dealer 360 Review at Winchester Equipment Company, the dealer team shared their ASEC progress to date. Winchester has coined the term “Follow the Yellow Brick Road” as their catchphrase for the journey down the ASEC Path.

In the early stages of Winchester’s ASEC journey, Mark McKinley, TMH Aftermarket District Manager, sponsored a trip to Lift Inc.’s Leesport ASEC Certified Location. Winchester Equipment Company’s team shared that they learned a lot from the trip and it provided them with the motivation they needed to begin the ASEC journey.

Winchester continues to make great strides in their ASEC journey. They are currently working toward their ASEC Certification, which is scheduled for August 2023. Based on the gains to date and the excitement of their associates, Winchester has already started to implement ASEC into their other non-Toyota businesses and locations.

Executive leadership and participation are crucial to building a strong foundation throughout the ASEC journey. Dealer Principal, Scott Carnell, wanted a simple visual that made it easy to identify the safe walking paths in the shop area and the “Follow the Yellow Brick Road” philosophy does that.

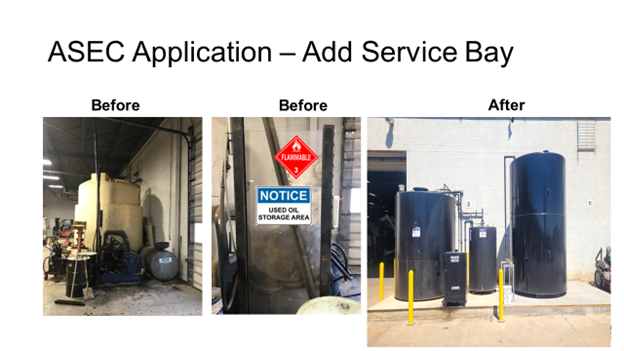

At their 360 Review, Winchester shared the move of a large indoor reclaimed oil tank to an outdoor area of their facility. Winchester credited ASEC with helping to identify the opportunity. The move helped to increase the “usable” interior square footage of the shop. The space gained created 2 additional service bays – creating additional revenue and profitability vs. a tank taking up space in the shop. Also, by moving the tank outside, it was easier and more efficient for the technicians to dispose of their liquid waste.

Other realized in-process ASEC efficiency benefits from Tommy Price, Continuous Improvement Manager, Winchester Equipment Company:

- Our Receiving Clerk has stated that certain tasks that would take 8 hours per day can now be completed in an hour (sometimes less) in large part due to ASEC. This savings frees up time for other tasks and projects.

- One of the Parts Associates stated that on large PM prep days, pulling parts for the technicians could take up to 4 – 5 hours. Now, utilizing the ASEC principles, that equivalent work, can be completed in less than 30 minutes. Again, freeing time up for other activities and contributions.

- After ASEC work began on the first set of service bays, other technicians wanted to volunteer to help re-organize the next set of bays.

Although Winchester remains on the journey to ASEC Certification, you can clearly see how the progress along the way can create excitement, motivation, and efficiency which, in turn, can convert to cost savings, profitability, recruiting advantages, etc.

If you have additional questions on Winchester’s in-process ASEC journey, you can reach out to Marty Bartlett, TMH Dealer Development Manager at marty.bartlett@toyotatmh.com or directly with the Winchester Equipment Company’s Tommy Price, Continuous Improvement Manager, directly at 540-667-2244 ext:123 or at tprice@winchesterequipment.com.