As part of the Dealer Development Best Practices Webinar Series, we conducted a dry ice blasting Webinar on Tuesday, June 27, 2023, at 11:00 AM EST. With Welch Equipment Company’s assistance, we introduced a dry ice technology called dry ice blasting to clean trucks (i.e., used equipment getting prepped for resale) and industrial equipment.

Dealer Development coordinated a technology discussion with Nick Andrews, Vice President of Sales and Marketing, and Keith Fine, Used Equipment Manager at Welch Equipment Company. Nick and Keith summarized Welch’s experience with dry ice blasting and their planned use of the technology moving forward.

During a recent Dealer 360 Review at Welch Equipment Company, Mike Parker was given a tour of the new building that Welch Equipment Company moved into 9 months ago. While awaiting approval for the new wash bay, Welch Equipment Company experimented with dry ice blasting. Welch’s sales tend to average approximately 70% electric. Washing electric units is tough as the power needs to be completely disconnected, and there is wait time for the components to dry. Dry ice blasting was quickly determined to be a viable solution, particularly for trucks that had been utilized in very dirty applications.

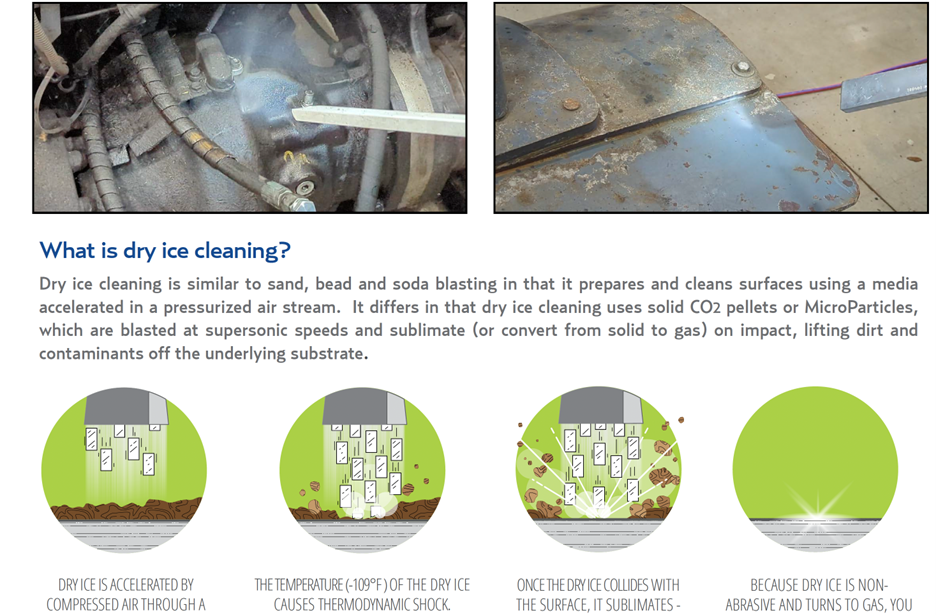

Simply stated: Put 2-3 bowls of ice into the dry ice machine and then blast it on the parts in the engine that need cleaning, even the hard-to-reach places. Compressed air from dry ice is sprayed out and collides with the surface of equipment, dislodging stubborn plaque and dirt on the engine surface.

Make sure you wear the required PPE!

Requirements to dry ice blast –

If your consumption of dry ice justifies making dry ice in-house, you would need to purchase a pelletizer. A pelletizer is a machine that produces solid-state dry ice from liquid CO2. Dry-ice blasting is utilized in many different types of industries. The unique properties of dry ice make it an ideal cleaning solution in many commercial and manufacturing settings.

Dry ice blasting, also called dry ice cleaning, is an environmentally sustainable cleaning and surface preparation technique. Dry ice blast cleaning machines use recycled solid carbon dioxide (CO2) pellets or MicroParticles, which are blasted at supersonic speeds and sublimate on impact, lifting dirt and contaminants off the underlying substrate. Dry ice cleaning is non-abrasive, non-conductive, non-toxic, and non-flammable, giving several advantages over other cleaning methods. CO2 blasting is also chemical-free, water-free, and does not create secondary waste streams. Our dry ice blasting equipment features unparalleled technology that can be used in a variety of industries and applications.

Dry Ice Production FAQs:

How is dry ice made?

Dry ice is the solid form of carbon dioxide (CO2). To create dry ice, recycled CO2 gas is pressurized and cooled to form liquid CO2 (LCO2) is then injected into a pelletizer or dry ice production unit. Within the pelletizer, the pressurized LCO2 is released to atmospheric pressure, which causes it to solidify into a snow-like consistency. Then, it is compressed into pellets, blocks, or slabs.

Can I make my own dry ice?

Dry ice can be produced on demand using a dry ice production machine (pelletizer or slice maker). Producing your own dry ice must be economically viable and the amount of dry ice used daily and weekly must be considered.

Pelletizers, slice makers, and reformers can be equipped with multiple dies to produce a range of extrusion sizes (3mm to 19mm) and final product sizes. Dry ice production equipment can produce, dose, and package multiple sizes of dry ice for a broad range of solutions.

Should I make my own dry ice?

In the right situation, making your own dry ice can save you a lot of time and money while eliminating headaches. Producing your own dry ice can give you greater control over your production, processing, and cold chain management systems while also reducing waste and cutting operational costs.

By answering a few simple questions, you can determine whether producing your dry ice is right for you. Those questions include:

- How much dry ice do you consume weekly/monthly?

- What are your current delivery costs?

- Is dry ice part of a critical path in your operation?

- Do you waste a lot of dry ice per week?

- Does your facility have a CO2 tank and three-phase power?

Dry Ice & CO2 Safety:

When working with CO2, precaution must always be taken to ensure that the area is sufficiently ventilated and that proper PPE is worn when dealing with the liquid or solid form of CO2 (dry ice).

The picture depicts – engine block:

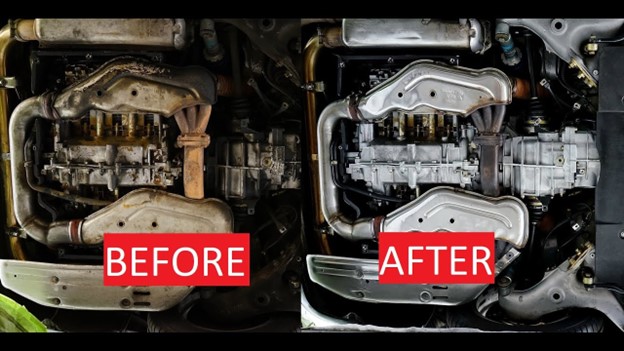

Another visual depiction of a before and after undercarriage of a forklift engine using Dry Ice:

Other dry ice blasting realized efficiency benefits for Welch Equipment Company

- Reduce downtime – Significantly quicker process leads to increased production time.

- Increase efficiency – Clean equipment online, while eliminating the need for cool down and disassembly.

- Non-abrasive – Dry ice is a soft medium that will not harm substrates.

- Environmentally sustainable – Dry ice is made of recycled CO2 and does not add additional CO2 to the atmosphere.

- No secondary waste- Dry ice does not produce secondary waste streams, residue, or moisture.

- Decrease landfill waste

- Colorless, tasteless, and odorless

- More efficiently allocate labor – The process reduces time, labor, and resources needed.

- Improved part quality and reduced scrap – Cleaner machinery and tooling result in higher quality products.

- Operator safe – Eliminates the need for chemicals and repetitive, manual processes.

Welch Equipment Company can clearly see the benefits and has already started to implement dry ice blasting into their other non-Toyota businesses and locations. By using dry ice technology, they have converted this into cost savings, better profitability, and a cleaner, safer truck to work on for their technicians.

If you have any additional questions in regards to dry ice blasting, you can reach out to the TMH Dealer Development team; Mike Parker Michael.Parker@toyotatmh.com; Greg Bowman greg.bowman@toyotatmh.com; Marty Bartlett marty.bartlett@toyotatmh.com, or directly with Welch Equipment Company; Nick Andrews – VP of Sales and Marketing NAndrews@welcheq.com, or Keith Fine – Used Equipment Manager kfine@welcheq.com.

We are also providing a link to the dry ice blasting Webinar that was conducted on Tuesday, June 27, 2023, at 11:00 AM EST. Click here to access the video.