As part of Dealer Development’s best practices, we have identified an excellent way to store electric pallet jacks and an additional way to keep the batteries charged. Liftow Limited has developed a vertical storage method and designed a racking system that has been incorporated into all of its facilities. We were excited to see the development of the storage system by Liftow Limited and the sharing and adoption by Thompson & Johnson as they enhanced this to add power in support of battery charging. This is a great way to support your storage concerns and the Toyota Material Handling (TMH) upcoming Consignment Program initiatives.

AWARD-WINNING PHOTO FROM TOYOTAWEEK 2024:

Dave McKnight – LIFTOW Corporate Facilities ASEC Manager – Development of Electric Pallet Truck Storage System:

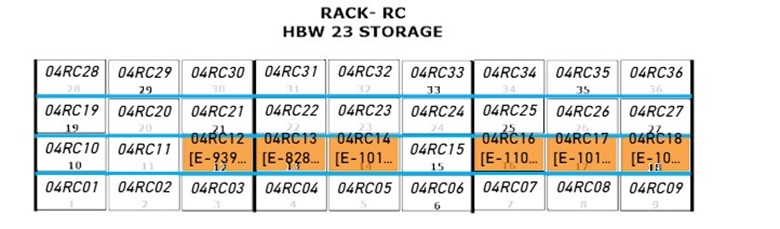

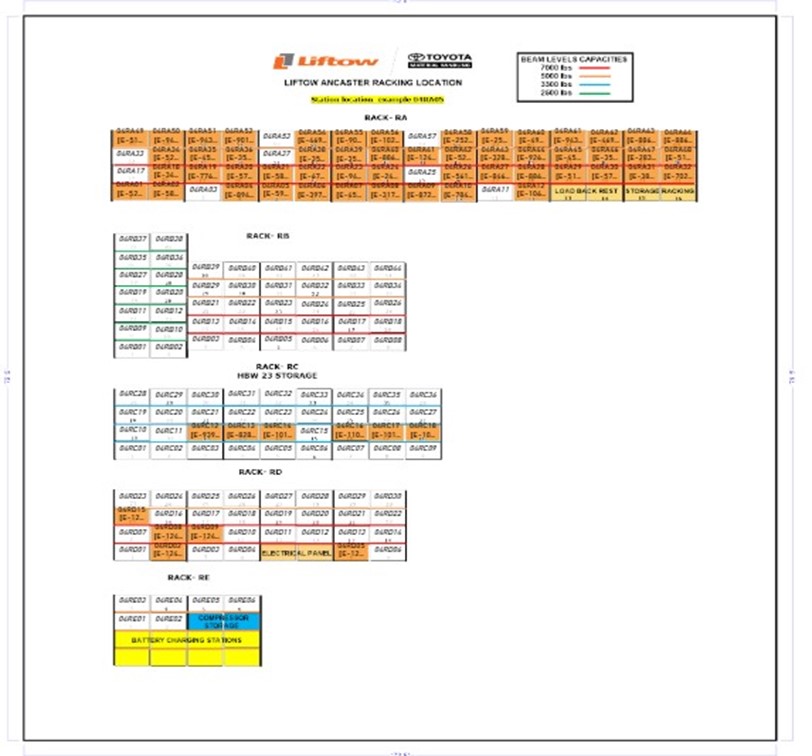

“Good day, team Toyota; we here at Liftow Limited developed this racking system with the help of Mike Miceli at Metrics Storage Systems to help us get our 8HBW23 pallet trucks off the floor and free up storage space at our branches in their warehouses. We created parking locations for our electric and propane power units with the warehouse’s free space. Additionally, with our IT department’s help, we created racking locations and a complete mapping system in Power BI.

The Power BI system shows when the space or location is occupied or if it is available for a unit to be stored. All mapping locations are white, but when a unit is in the racking location in the ELC, the area on the map in Power BI will turn orange. The equipment number installed on the map shows the unit stored in that location. This works well when sales representatives are looking for a unit to show the customer. Overall, this has been a great asset to Liftow Limited in managing the storage of the 8HBW23, and it has freed up valuable warehouse storage space.”

Mark Benedetto, Director of Operations from Thompson & Johnson – Kaizen for the Pallet Truck Storage Rack:

“We used the Liftow Limited racking and pallet design for our walkie pallet jacks to save floor space. They were gracious enough to send their drawings and drawings for the custom pallets that the trucks were loaded on for easy maneuverability in and out of the higher rack levels. Our racking can hold 27 – 8HBW23s or 18 – 8HBW23s and 6–8HBE30s.

Once we loaded our rack, we discussed how to charge these trucks monthly without pulling them out of the racks or moving an extension cord to each truck.

We decided to install three electric cord reels to handle the job. We had an electrician wire them into our existing power lines and then attach them to the top of the racks. Each month, one of our employees will start at the top (using a man lift) and work their way down the racking until they charge all the trucks.

Each cord reel can charge three trucks at a time. If the rack is full, charging all the units takes three days.”

If you need vertical storage, you should consider placing a custom pallet order as Liftow Limited and Thompson & Johnson did. See the photo and dimensions; this design locks the drive wheel in place and is strapped down for safe storage.

Pallet Dimensions: Pallets are 72’’ x 30’’ x 5 ¼.

Other realized efficiency benefits:

- Reduced floor storage space

- Increased efficiency

- Inventory control

- More efficient labor allocation

If you have any additional questions regarding the storage and charging of electric pallet jacks, you can reach out to the following individuals:

- TMH Dealer Development Team

- Mike Parker: Michael.Parker@toyotatmh.com

- Greg Bowman: greg.bowman@toyotatmh.com

- TMH District Sales Manager

- Marty Bartlett: marty.bartlett@toyotatmh.com

- TMH Aftermarket District Managers

- Barry Bonner: barry.bonner@toyotatmh.com

- Mark Mckinley: mark.mckinley@toyotatmh.com

- ASEC Manager with Liftow Limited

- Dave McKnight: dave.mcknight@liftow.com

- Director of Operations with Thompson & Johnson

- Mark Benedetto: MBenedetto@thompsonandjohnson.com