Last spring, Thompson and Johnson (T&J) completed their first process mapping event with the Toyota Lean Management (TLM) team. T&J mapped the road work order process and created several kaizen actions that resulted in team efficiencies and customer benefits.

- Before the event, jobs averaged 5-6 hours over estimated time. Now, jobs average less than an hour.

- Improvements in the quoting process resulted in a 5% increase in the number of quotes generated, and the closing rate increased from 58% to 75% with improvements in information accuracy.

- Service Writers, Technicians, Warranty, and Service Coordinators developed a quote form that provided the correct information so quotes and warranty claims can be processed faster.

- Dispatchers developed a 15-question outline that each dispatcher follows when talking with the customer. This ensures the correct information is received, improving communication and the billing process.

After successfully mapping the work order process, the Thompson and Johnson team wanted to tackle their sales order process.

“Our sales coordinators are overwhelmed with work. T&J recognizes the value of our employees and determined the only way to address their concerns was to hire more staff or develop better process flows. Our goal was to streamline activities to create more time to accomplish productive work functions.”- Tim Gaughan, Director of Sales & Marketing

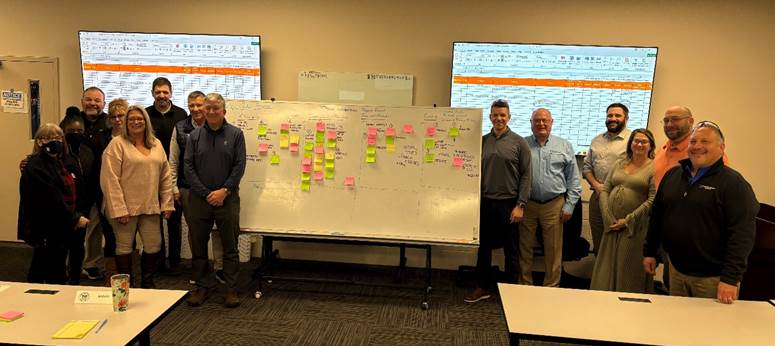

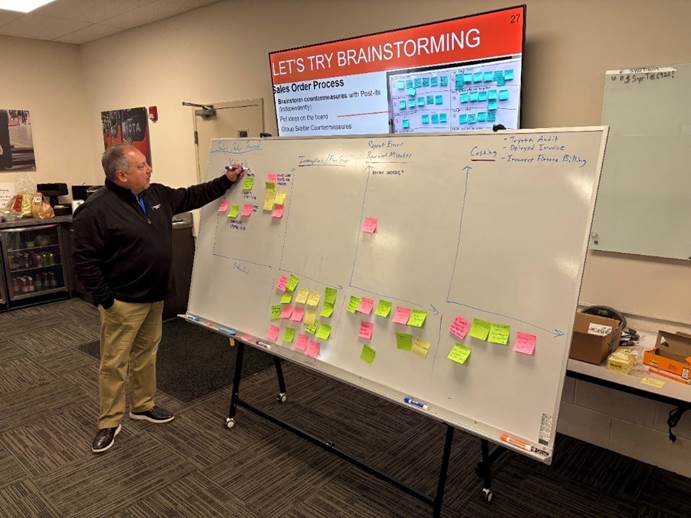

Determining all the stakeholders was one of the first steps in mapping the sales process. T&J ensured that a representative from each part of the process was present. A key part of process mapping is hearing from people who do the process to learn from their expertise. Eleven team members received Lean Basics training from the TLM team and proceeded to map their process led by Lean Champion Mark Benedetto, Director of Operations. The current state was mapped first, followed by identifying waste and problems. Then, the team brainstormed countermeasures for their largest opportunities and created an action plan.

“It was very rewarding for me to lead the event; the group did all the work, and seeing the “AH HA” moments was awesome! That is when the event took on a new life, and the group took on a new outlook. They believed what they were doing was going to make a difference. It was inspiring to see people from different departments come together and create a “Better Way” of doing something.” – Mark Benedetto, Director of Operations

After the event, the team met weekly to ensure that countermeasures were identified and any roadblocks were removed along the way. The following are a few activities from the event’s action plan that began in the first month.

- A daily 8:45 am virtual Sales Coordinator meeting was initiated. All team members working with the Sales Coordinators were invited to participate and address any concerns. This alleviated daily interruptions for the Sales Coordinators to increase their value-creating time.

- Access to portals was increased for the sales staff, further minimizing sales coordinator interruptions.

- The VSimple Portal process, which tracks leads and orders, has been streamlined. This assists Sales Coordinators with the flow of their ordering process.

Process mapping events delivered results for our team, customers, and other team members by helping them learn about Lean culture and apply a kaizen mindset.

- “We learned that the workflow process is undergoing continual improvement. Never be satisfied and keep searching for a better, more efficient way to accomplish tasks. This process will achieve the best results with total team collaboration. We would certainly do a process mapping event again and recommend it to other dealers. Day-to-day activities can prevent leadership from developing necessary workflows. We need to spend time developing processes and go to the experts (those who perform the process every day) for guidance and advice.”- Tim Gaughan, Director of Sales & Marketing

- “We knew that our processes were not fully documented, not to mention applying lean principles. These TLM sessions have produced a greater understanding for all of our stakeholders, and I believe it will reduce a lot of stress within the departments.” – Dave Schneckenburger, President & CEO