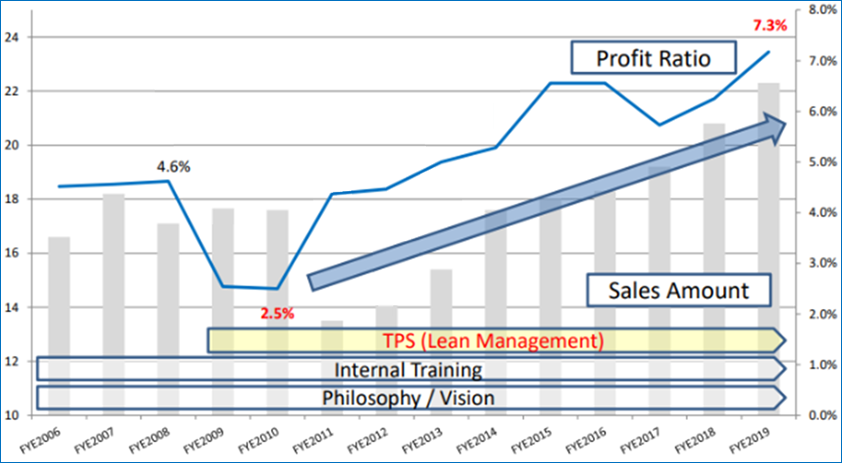

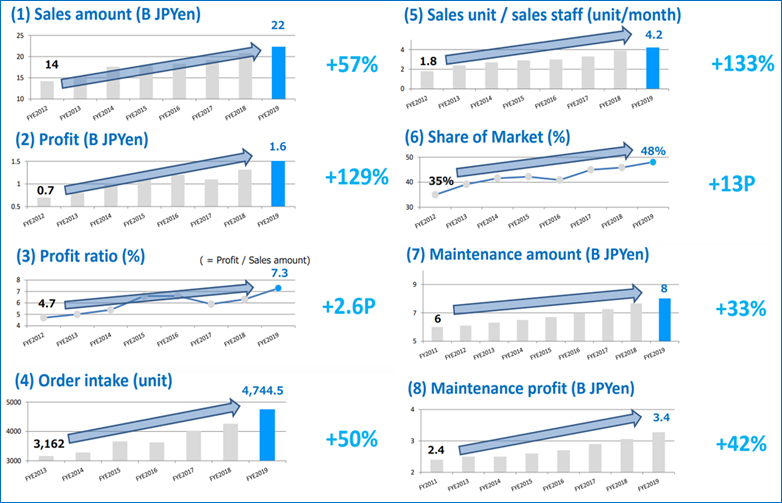

L&F Kinki, a dealer in the Toyota L&F network near Osaka, Japan, experienced a significant drop in its profit ratio in 2008. Total sales, market share, participation ratio, and market recognition ratio were all down. This drove the company to try something different: adopt Toyota Lean Management. This change led the organization to systematic improvement year after year.

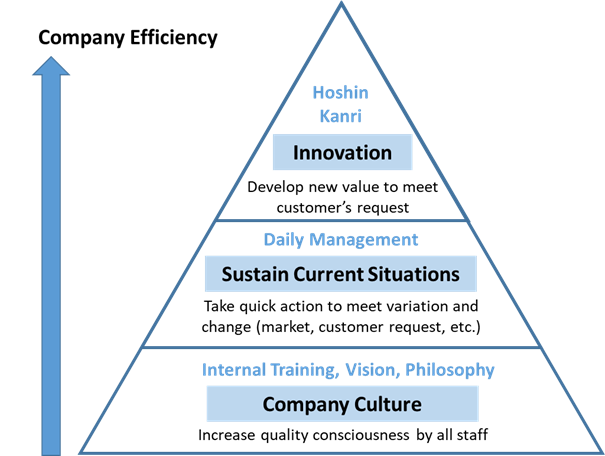

They began the Toyota Lean Management journey by focusing on their company culture. Their goal was to increase quality consciousness of all staff. The first step was to create a vision for the company, focusing on supporting the customer, employees, and society. Then, they bolstered this foundation by creating internal training programs to increase skills for each position and apply the Toyota Lean Management philosophy. Top management involvement is necessary for success with Lean culture; L&F Kinki was no different. At L&F Kinki, top management drove the culture change and taught Toyota Lean Management skills and philosophies to their teams; calling it the Kajiwara Management School.

Following the training, they started developing the management system and refining the processes that support it throughout the organization.

| Process Focus | Management System Focus |

| 5SStandard WorkManage Quality at Each Process | Hoshin Kanri (HK)Daily Management (DM)Top Management Audits both DM and HK |

| Methods for both | |

| Turn the PDCA (Plan Do Check Act) Wheel to solve problems, eliminating root causesMake decisions with facts and data | |

The Management System focused on implementing daily management and Hoshin Kanri in the dealership branches to drive improvement in company efficiency. Both management methods are implemented by establishing KPIs (Key Performance Indicators) for the processes. Daily management sets a measurable standard to achieve and visualizes performance to that standard daily. These daily results are reviewed with the team for reflection and action. Hoshin Kanri sets measurable targets for the three to five initiatives to improve the business. Progress for these key initiatives is visualized. PDCA problem-solving is used to address below-standard and below-target conditions in both management processes.

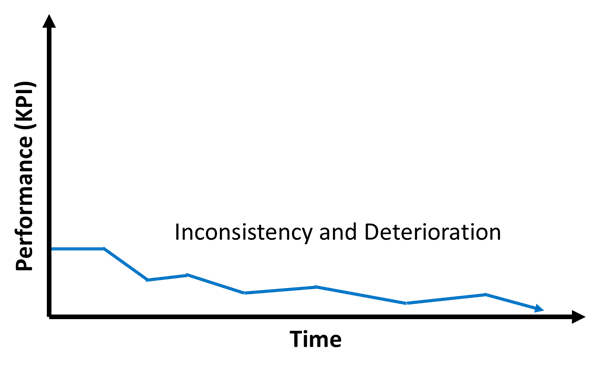

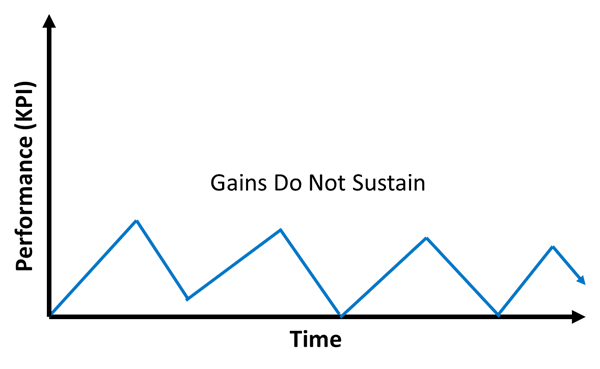

| No Management System: Without a Lean Management System, processes will struggle to maintain stability and may deteriorate. |  |

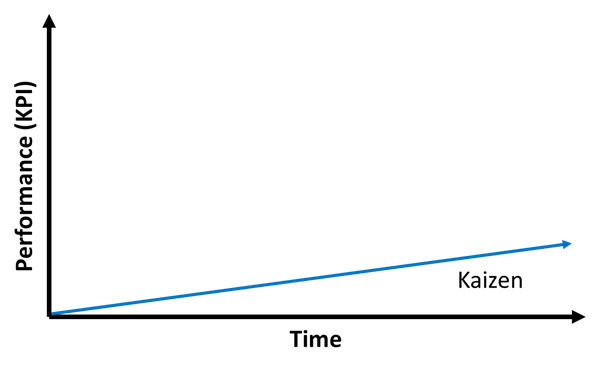

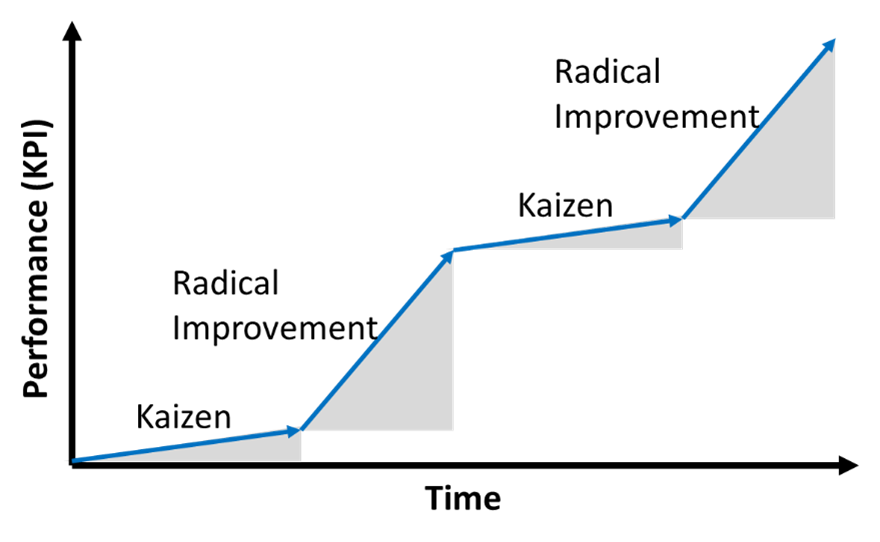

| Daily Management (DM): Every process requires a daily management process. The goal is to sustain current conditions and kaizen the process. Kaizen is usually small changes that add up over time. This will stabilize and improve the business, but radical improvements are less likely. |  |

| Hoshin Kanri (HK): HK focuses on significant targeted changes to the business. If only large strategic initiatives are the focus, improvement gains will occur, but those gains will rarely be sustained over time. Therefore, performance fluctuation will be significant. |  |

| Daily Management + Hoshin Kanri: Practicing both DM and HK provides the benefit of creating large gains in targeted areas of the business and sustaining those gains while maintaining and/or improving all company processes. |  |

Practicing DM and HK brings problems to the surface. These problems are represented by gaps in data that are visualized in a chart. These graphs show the data of the current condition measure vs. the standard/target condition. Problems and opportunities are identified in this manner and addressed using the PDCA (Plan-Do-Check-Act) problem-solving process. In daily management, the condition of all processes will be reviewed daily. In Hoshin Kanri, projects and their metrics are reviewed monthly, with a strategic plan review every six months.

Here are only a few opportunities that surfaced during the TLM application and their countermeasures

| Work | Opportunity | Countermeasures |

| Office Work | Long and numerous meetings | Focus on short daily management meetings |

| Office Work | Many different management formats and processes | Standardized work processes to reduce work time |

| Sales Activity | Inefficient visits to customers, infrequent visits to customers, travel time waste, and avoiding customers | Sales team members create a sales activity plan, visualize progress, provide daily communication, and reporting |

| Progress Management | Management methods and progress evaluation are not consistent among branches | Standardize management method and data reporting so the manager can advise |

| Skill Level | Different procedures throughout the company for the same process | Create standard work procedures and continue to develop the training program |

After years of activity and following the daily management and Hoshin Kanri processes, top-level metrics in the company improved year over year. Drastic improvements can be seen in three key metrics (Profit, Profit Ratio, and Sales Units per Sales Staff) following changes to the business Hoshin Kanri activities. Through top management’s commitment and focus on Toyota Lean Management, L&F Kinki is able to continually improve its efficiency, contributing to its vision of supporting customers, employees, and society with measurable results.

Wherever your dealership is on the Lean path, the TLM team can help. If you are just starting, we can review the Leadership Foundations, Lean Basics, and Lean Champion Training with you. If you are further along the path, our offers include a 1-2 day Hoshin Kanri Workshop for the dealership to create a strategic plan, as well as Daily Management Training to learn about focusing on sustaining current processes and solving problems.

For TLM help and questions, reach out to Lean Business Development Senior Manager, Logan Fowler, at Logan.Fowler@toyotatmh.com.