When the service department dispatches a technician on a truck down call, the goal is to get our customer’s forklift up and running as quickly as possible. Achieving this goal requires having the right parts in stock on your service vans. Ensuring the right parts begins with implementing proper inventory control.

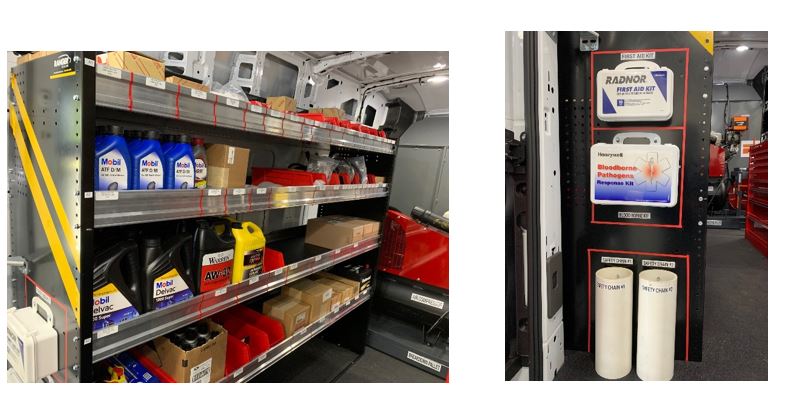

Historically, taking inventory on a service van could take four hours or more of unbillable time. To improve on this process, Toyota Material Handling Systems (TMHS) has implemented the core principles 5S and ASEC into their service vans.

To ensure success, TMHS’ Corporate Parts Manager, Kerry Swafford, and TMHS’s Parts Manager, Raul Albertus, began the process by working diligently to earn buy-in from their road technicians. Kerry and Raul utilized parts sales history to identify the high in-demand parts. Working closely with the technicians developed the culture of 5S / ASEC on the vans. Now each technician takes full ownership and pride in the 5S condition of their vans.

The investment in 5S / ASEC principles has produced tremendous results for TMHS and their customers including:

- Van inventory has been reduced from four hours down to less than thirty minutes

- Improved customer satisfaction with increasing first-time fix rates

- Produced a more efficient and lean parts operation by increasing parts turns without negatively affecting Stock to Critical Ratio

TMHS’ VP, Joshua Smith summarizes, “At the end of the day, our customers benefit from this lean process. Keeping our technicians in the field, keeping their equipment running. Making sure the right part is on the van at the right time.”

For more information on TMHS’ Lean Service Van Inventory program, watch the video available here.