During a recent 360 Review with The Lilly Company, we identified an area of importance in which we wanted to share their best practices with our dealer network. Therefore, Rick Gilleland from The Lilly Company has graciously provided a best practice for their internal process to support the management of Planned Maintenance to include PM agreements, Full Service Maintenance Plans, and Fleet Customers.

The PM is an agreement between the dealer and the customer, stating that maintenance and inspection will occur at specific intervals. PM completion is important for several reasons; signing your customers to a PM contract will help keep your competition away from your customers, and regular maintenance will keep your customer’s equipment operating efficiently, thereby lowering the cost of ownership. Staying on top of your customer’s maintenance needs will also create opportunities to sell additional parts and labor. From a dealer perspective, you can sell additional parts, services, and rental equipment.

The Service Manager, dispatcher, and service clerk should all be active in managing PMs and their respective PM completion rate.

PM Scheduling and Reviewing:

- Run the PM list on the first of the month and distribute it to all technicians.

- Record how many PMs each technician was given.

- The service department should track each technician’s completion performance. Technician workload can be managed to help balance service work and PMs if needed. This should be done at least once a week, ideally on the same day of each week for consistency purposes.

- Five working days before the end of the month, the service department should review all PMs not completed and apply their resources accordingly.

Best Practice: If one of the better technicians still has a large number of PMs to complete, a less experienced technician can be pulled from another territory to assist. This allows the experienced technician to continue to take service calls.

- Remove inactive and/or canceled PM agreements. It is important to keep a “clean” list of active PMs. Too often, overall PM Program effectiveness is distorted because inactive trucks such as off-lease trucks, for example, replaced with new equipment, are not deactivated in the dealer business system, or canceled PM agreements are not deactivated in the dealer business system. This results in wasted time opening work orders, adding PMs to tech schedules, and wasted customer visits for trucks no longer under a PM agreement.

Benchmark: PM completion rate should be no lower than 90% with the goal of 100% every month.

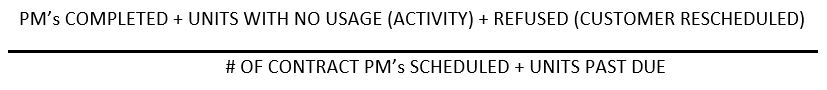

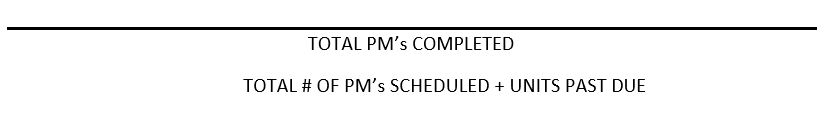

Completion Rate Formula: Completion rate performance is calculated in monthly terms, and should be calculated two ways. One calculation will provide an indicator of technician performance, while the other will determine the overall effectiveness of your PM program.

Technician Performance- This calculation takes into account the overall number of PM’s that the technician could reasonably be expected to perform. A PM should be considered complete, even if the work was not done, as long as the customer signed a PM inspection report stating they did not want the dealer to do the PM on that visit or if there weren’t enough hours on the truck to warrant PM work. If the dealer misses a PM when it is due, and there is an incident with that piece of equipment, the dealer can be held liable in some states.

Overall PM Program Effectiveness- This is a simple calculation of the overall number of PMs completed divided by the total number of PMs scheduled. A low percentage would indicate deficiencies in your PM program. Customer follow-up will be required to determine why your PM program is not meeting your customer’s expectations.

Common errors that cause unwelcome results in PM Completion Rate:

- Scheduling conflicts with the dispatcher. When customers want to push or delay a PM, take the time to explain that service technicians are busy and we may not be able to reschedule before the next PM is due. Customers understand the technicians are busy, and we have had success getting customers to allow the scheduled PM if they don’t think they can reschedule in a few days. Our tech time is valuable, and we work to maintain an efficient schedule, delays accessing the scheduled PMs disrupt the tech schedule, which can also affect other customers.

- The technician’s time is poorly managed. Typically PM services are a flat rate + parts. We do not charge customers travel time for a PM service if they are on contract. Service Managers, dispatchers, and technicians should schedule repairs and warranty campaigns during PM services when possible or in the same area as scheduled PMs to minimize lost travel for PM services.

- No tracking procedures are in place to record the PMs that are being completed.

PLANNED MAINTENANCE ASSIGNMENT OPTIONS:

There are different approaches applied by dealerships when it comes to Planned Maintenance scheduling. The following factors can determine a Dealer’s PM strategy:

- Size of Dealership

- Geography

- Market structure

- UIO (units in operation)

The key is providing reliable PM service that assures the customer their investment in your PM program will keep their lift trucks performing optimally.

Recommended PM Method:

Assign PMs to technicians by territory when possible.

- The technician and the customers get to know one another and build trust.

- This makes it easier for the technician to get additional work approved.

- It is easier to monitor the number of PMs performed by each technician.

- It is easier to quality-check the technician’s work.

Best Practice: It is recommended that all technicians do PMs. The PM is the starting point for additional parts and service sales. Ideally, all the technicians would work PMs and sell the follow-up work. It will also eliminate the number of times a truck is down for work. Better technicians have fewer and/or more important customers assigned to them. Newer technicians have more PMs and would include many of the 1-10 truck type accounts.

What should a Dealership do when a PM Customer continues to cancel or reschedule?

Best Practice: The key is in your communication. Have your Technician and/or CSS schedule an appointment when there is the opportunity to point out to the customer the purpose and benefits of having a PM program for their lift truck. Evaluate and design a PM program that meets your customer’s needs. If the customer is going through a slow time where they’re not using their lift, ask them if they would be interested in postponing a regular PM schedule until an agreed-upon date. However, remind them that if they resume regular operation of their lift trucks, they should get in touch with you or your dealership immediately to schedule regular PM practices. Give your customer options. Don’t send the wrong signal to your customer by dropping their PM schedule.

Planned Maintenance when designed and managed correctly is a win-win for the customer and the dealership!

If you have any additional questions, reach out to Greg Bowman at greg.bowman@toyotatmh.com with TMH Dealer Development or directly with Rick Gilleland rgilleland@lillyco.com with The Lilly Company.